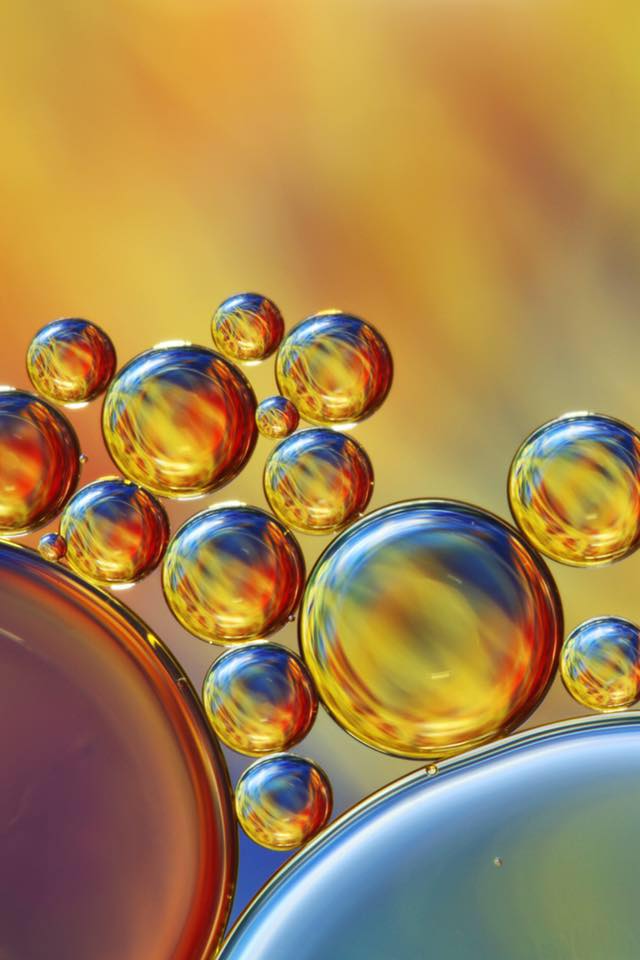

Nowadays, you can find CBD infused into practically anything. But, the process of cannabis infusion is not an easy one, and it’s not something that every company gets right. However, that’s where experts like Vertosa come into play.

Vertosa is a cannabis infusion company that helps brands such as CANN, Hi-Fi Hops, Wunder, and Keef flawlessly blend their products with cannabinoids. They’re focused on crafting only the best, most efficacious delivery systems possible for the cannabis industry. This way, not only do customers get to enjoy seamlessly blended cannabis food or drink, but they get all the potency of the cannabinoids themselves.

Created by an emulsion scientist, Vertosa knows a thing or two about intertwining science and plant medicine. But, more than anything, the company is dedicated to breaking stigmas and providing consumers with a new perspective on cannabis consumption. Now, through their advanced cannabis emulsion technology and nationwide partnerships, Vertosa is doing all of that and so much more.

Interview with Dr. Harold Han, the Founder of Vertosa

Today, we’re sitting down with Dr. Harold Han, the founder and CSO of Vertosa. We wanted to know more about the infusion processes that his company has perfected, and further understand the complexities behind emulsion technology applied in cannabis foods and beverages. Graciously, Dr. Han gives us the inside scoop about cannabis infusion, infused foods and beverages, and so much more.

For those new to the cannabis infusion space, what makes a good/proper infusion?

DR. HAN: There are five words that should be top of mind when evaluating if an infused product is properly produced: palatable, stable, predictable, repeatable, and scalable.

First of all, an infused beverage or food must be palatable, in other words, it must taste good to gain consumer attention. It can’t taste too much like cannabis — although certain product types may use that flavor as a unique selling point — or have an overall bitter taste. It’s best when the cannabis emulsion either complements the existing flavors or is flavor neutral, offering more room for manufacturers to achieve the taste that they want to deliver.

Equally important, the infused product must be stable throughout its shelf-life. There should not be any physical deterioration such as separation, O-ring formation or sedimentation, nor any chemical degradation which can cause cannabinoid potency decay. Cannabis emulsion’s compatibility against other ingredients, thermal processing conditions, packaging types, and dissolved oxygen may all become common threats to the stability of an infused product. A number of tests are needed to establish confidence prior to launch.

To build trust with consumers, the infused product must also be predictable. For example, most people can predict how they’ll feel when consuming wine or beer based on prior experience; cannabis-infused products need to be just as predictable when it comes to building trust and consuming habits.

Repeatability is also key. When consumers pick up the same brand in California or Canada, in March or December, they should have the same flavor and experience. These expectations add a number of supply chain and manufacturing challenges which the industry as a whole is currently working hard to address.

Last but not least, all features mentioned above need to be scalable. Not only should you be able to produce 20,000 cans from a 300-gallon tank, but the same technology must also produce 20 million cans at a larger facility with the same potency, homogeneity, flavor profile, and experience.

How far have we come since the early days of the first CBD drinks hitting the shelves or even homemade goodies?

DR. HAN: We’ve made significant progress across the key product characteristics already highlighted like taste, stability, predictability, and scale. In the early days of cannabis emulsion technology, the resulting infusion wasn’t very compatible or stable. It would typically rise to the top of the beverage or break down. This left consumers with unpredictable products – sometimes you never felt it, sometimes it knocked your socks off.

Homemade goodies also weren’t scalable. You can make 1,000 gummies with older technologies, but those methods will not deliver 100,000 gummies of the same quality.

Lastly, the first wave of infused products rarely ever had a pleasing flavor, making it difficult to manufacture edibles or beverages that consumers liked.

Is there a difference in the methods used for infusing CBD vs. THC? What about minor cannabinoids, like delta-8 vs. CBN vs. CBG?

DR. HAN: In theory, emulsions are agnostic, meaning we can change the core of the active ingredient and still use the same “shell” for the emulsion regardless of what cannabinoid is being infused.

But when you drill down into manufacturing emulsion at scale, you’ll find that different inputs can affect the end product. Such trends are often only identified after producing large batches of emulsions on a regular basis. When an anomaly is identified, we then adjust the emulsion ingredient ratio or physical processing conditions in order to achieve a consistent end product.

Does the infusion process change at all when working with different foods or drinks?

DR. HAN: Absolutely! Understanding how and where an emulsion can be integrated into the beverage and edible manufacturing process is very important. Infusing a beverage like soda is relatively easy because there is no sedimentation whereas something like kombucha has natural sediments that can be tricky to work with. In the latter case, the emulsion will often bind to those natural sediments and get dragged to the bottom of the bottle, thus leading to separation and unequal distribution of the active ingredient(s) in the drink. As a result, these types of beverages require a different manufacturing process to ensure consistent potency and a predictable experience for consumers.

The infusion process for food can also be dramatically different depending on the form factor. Gummies, candy, chocolates, and cookies each pose unique challenges that must be addressed. Regardless of the form factor, we work closely with product developers and manufacturers each step of the way to design the most delicious and effective infused products. The ingredient provider needs to work closely with the manufacturers at each step of the process, as well.

How can the average consumer tell the difference between high quality and low quality cannabis infused products?

DR. HAN: We can look back to the five characteristics of a proper infusion for this answer. Does it taste good? Do you have the same experience each time you try it? These may seem like simple questions but they are a great starting point when evaluating infused products, especially given the lack of consistency across the cannabis industry at this time. As consumers become more familiar with the effects brought on by cannabis-infused products, they will be able to judge how predictable products are in the same way they might with beer or wine.

What is an “active ingredient”? How do other active ingredients interact with cannabis?

DR. HAN: We define an active ingredient as one that can change your physical or mental state, or offer healing benefits. As such, active ingredients like cannabinoids help define the functional impact or promised effect of a product. In a cannabis-infused beverage, for example, the active ingredients are cannabinoids. Even though they can be incorporated in very low amounts, sometimes below 0.005% of the total beverage weight, they help alter your mood or physical state and create the intended effect of the product.

Another example of an active ingredient is Vitamin C, which can deliver an antioxidant benefit to consumers when incorporated into products like seltzer water or dissolvable tablets. Active ingredients can be water-soluble like Vitamin C or fat-soluble like THC and CBD and may require different infusion techniques to ensure the end product is palatable, stable, predictable, repeatable, and scalable. More research is needed to evaluate how various active ingredients impact the way cannabinoids behave in our body and Vertosa continues to invest resources and engage scientific experts to further develop our understanding and use of these ingredients.

Are there any food or drinks that can’t be infused, or that you find the most difficult?

DR. HAN: Virtually all food and drink can be infused because they’re either water-based or fat-based — and we can customize our ingredients to work with either. For example, while our forte is infusing water-dominant products like beverages and gummies, we also have a dry powder that can be infused into fat-dominant products.

How does the type of emulsion affect onset times?

DR. HAN: Onset is mostly affected by the emulsion droplet size. Smaller droplets typically offer a quicker onset time — I say typically because there might be examples of other factors that affect onset time. As much as we want to share what we know, we also need to be clear on what we do not know.

Small droplets offer a faster onset time because they are more easily transferred into the mixed micelle, which is the only vehicle through which fat can be absorbed inside the small intestines.

What insights can you share about the research Vertosa is conducting to understand the bioavailability of your emulsion formula?

DR. HAN: We are applying to the Institutional Review Board (IRB) for approval of our THC bioavailability study. The IRB will review the study to ensure it is well-designed and safe for participants. There are many hurdles to receiving an IRB approval because THC is not federally legal nor FDA-approved.

If approved, we will conduct a Pharmacokinetic (PK) study in a DEA/FDA-certified lab. That will entail taking multiple blood samples from patients who have consumed THC in beverage or gummy form to analyze the THC concentration in their blood over a set time period. This research will help us expand our understanding of how our body absorbs cannabinoids, ensure the fundamental safety and efficacy of our products and help us better educate both our clients and consumers.

Which cannabis-infused categories are trending right now? What trends do you foresee in the next few years?

DR. HAN: Functional ingredients and health-focused products are trending in both mainstream CPG markets and the cannabis industry. Consumers are looking for beneficial compounds like vitamins, adaptogens, botanicals, and terpenes in addition to cannabinoids in infused products. As these trends evolve, and the cannabis supply chain develops, Vertosa will continue to refine our offerings and expand our research to help our clients design unique experiences for consumers.

Final Thoughts

Plain and simple, cannabis infusion is a complicated process. That’s why the industry is so grateful to have companies like Vertosa who are not only well-versed in emulsion, but who are dedicated to furthering the cannabis sphere, too. Thanks to names like Vertosa — and experts like Dr. Han — people like you and me get to enjoy our favorite foods and beverages infused with CBD and THC.