Most people encounter CBD in an already extracted and possibly isolated form. With the booming market for CBD oils and extracts, it’s not a surprise that casual consumers never have to really consider the whole process involved in putting together the oil or tincture they’re enjoying.

But if you want to get the right product for your needs, it helps to learn a little bit more about the process for making CBD, and how the different processes used affect the end-result.

Don’t worry, though, we’re not going to get super-scientific on you here, just provide a run-down of the key points you should keep in mind when making your next purchase.

At a Glance: Here’s How CBD Oil is Made

- From a starting point of (usually) hemp, manufacturers extract the CBD and then process the extract.

- Supercritical CO2 extraction is the most common, and produces a high-quality extract with no risk from any residues.

- Liquid solvent extraction works in a similar way but uses ethanol, butane, pentane or another hydrocarbon solvent, which is then boiled away (although it may leave residue).

- Finally, oil infusion and lipid extraction is more of a “home-brew” method where the material is heated in oil or fat to extract the cannabinoids.

- Winterization processes the extract by freezing it in alcohol and then filtering out the lipids from the mixture.

- Short path distillation separates individual cannabinoids through a slow, controlled heating process, which can be repeated multiple times for a purer extract.

CBD Extraction Isn’t (Necessarily) About Purity

Before getting into the details of what manufacturers do when making CBD oils and extracts, it’s important to be clear about the goal of CBD extraction.

You might think that getting the purest CBD possible is the key goal, and while this is true in some cases (for isolate), most of the time users want a little more than just CBD.

For example, other cannabinoids are present in plants at lower levels and you don’t always want to remove these, and there are also the terpenes, which are responsible for the taste and smell of the cannabis plant.

Researchers call the key point behind all this the “entourage effect.” In short, while CBD alone will have benefits, the combined effect of multiple cannabinoids is where the magic really happens.

There isn’t much data on this point, but cannabis consumers are generally united on the point that the effects of single cannabinoids aren’t quite the same without support from the many chemical compounds in the plant.

This is why getting completely pure CBD often isn’t the goal of the manufacturing process: many people prefer “full spectrum” or “broad spectrum” extracts.

Most Manufacturers Use Hemp for CBD Oil

The process of extraction and processing into a purified oil can be completed with either traditional, higher-THC cannabis strains or simply with low-THC hemp.

Because there are essentially no legal issues with hemp (after the 2018 Farm Bill), this is much more commonly used because it’s always below 0.3% THC and almost no THC will make it into a final product.

On the other hand, traditional cannabis plants tend to have a lot of THC, with even high-CBD strains still having roughly equal amounts of CBD and THC.

The THC causes the issue if you aren’t living in a state with recreational or medicinal legalization. If you are, and you want to get a little high or experience the combined effect of THC and CBD, then a fully cannabis-derived oil is perfect.

But in most cases if you’re looking for CBD oil, you don’t actually want to get high, and so for that and legal purposes it makes more sense to go with a hemp-derived oil.

However, keep in mind that hemp oil (aka hempseed oil) is not the same as CBD oil – CBD oil derived from hemp is good, whereas hemp oil contains much less CBD.

For the production of CBD oil (generally) only “female” hemp buds are used. After over 100 days of growth, buds are harvested and dried at 25 °C / 77 °F e.g.

CBD Oil Extraction Methods

The first phase of the manufacturing process for CBD involves getting the cannabinoid out of the plant and into a usable form.

Companies use a few different methods to accomplish this, and the choice they make is one of the most important things to consider when you’re deciding between different CBD products.

CO2 Extraction

CO2 extraction is the most popular extraction method for CBD in use today, and it’s one of the most reliable and effective methods too.

The main reason for this is that CO2 is generally regarded as safe by the FDA, and so any residue leftover from the extraction process is completely non-toxic. The actual process of supercritical CO2 extraction is quite technologically demanding and getting initially set up is expensive, but the quality of the extract definitely makes it worthwhile for companies.

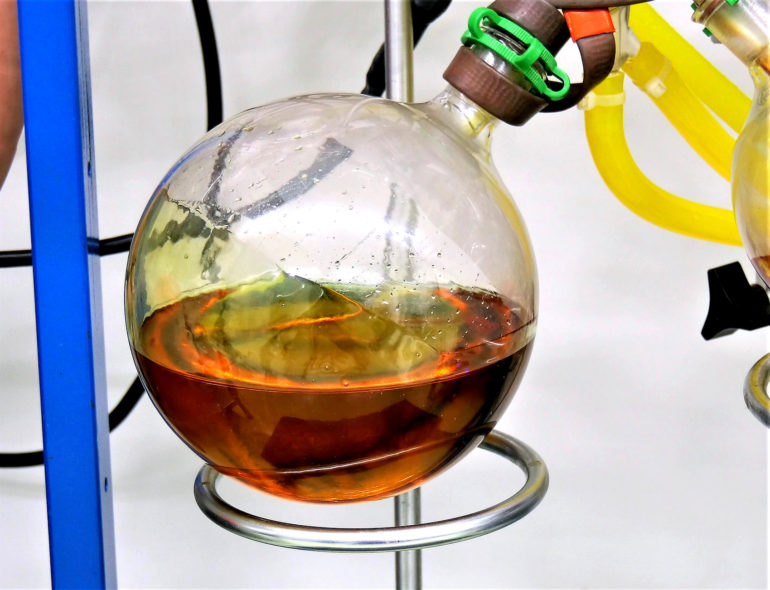

The process basically involves using CO2 (carbon dioxide) at high pressures and a precisely-controlled temperature to strip the CBD and other important chemicals from the plant. Ordinarily, CO2 is a gas, but it can be a solid (“dry ice”) at certain temperatures and pressures, and also, crucially, a liquid. This requires temperatures below −69 °F/−56 °C and a pressure above 75 pounds per square inch, and if you slightly increase the temperature and pressure above this point, it becomes “supercritical.” This supercritical state is vital for the extraction, because it maintains some of the key qualities of the liquid form (especially the density) while expanding to fill a container in the same way as a gas.

This basically means the CO2 is somewhere between liquid and gas states, and this is the stage that’s perfect for CBD extraction. When you push CO2 in this state through some hemp or cannabis, it removes the trichomes and terpene oils while leaving the undesirable elements like chlorophyll.

At this point, manufacturers pass the mixture through a separator, where the extracted components are collected as the CO2 is allowed to return to a gaseous state (or is condensed back into a liquid for re-use).

Liquid Solvent Extraction

For a long time, extracting the CBD and other cannabinoids using liquid solvents was the most common approach.

In particular, ethanol (i.e. drinking alcohol), butane, pentane, hexane and isopropyl alcohol are often used for this purpose. The process basically works in the same way as CO2 extraction, but crucially there is no need to get the material into a supercritical state and so it’s much cheaper and simpler to accomplish.

When you use liquid solvents like this for CBD extraction, you run in to a few issues, in particular that impurities such as chlorophyll find their way into the extract, and that the process may leave behind some undesirable residue from the solvent. Ethanol solves the residue problem (because even if it’s there, it’s non-toxic) but rectifying the issues with impurities is more difficult, because most of the time, trying to filter these out will also result in a loss of cannabinoids.

However, unless you have a very experienced operator working with ethanol extraction, the results of this approach aren’t the same as CO2 extraction in terms of cannabinoid content.

Often, terpenes and CBD aren’t as well captured using this approach, while it’s OK for THC. All of this explains why most companies don’t use liquid solvents for CBD extraction.

Oil Infusion and Lipid Extraction

Using oils or lipids (i.e. “fats”) to extract CBD from the plant offers a simple method, but it also results in a lower-strength extract and it requires a bit of preparation.

First, the plant material has to be decarboxylated (this is needed before our bodies can absorb CBD or THC), which basically means heated in order to activate the cannabinoids.

After this, manufacturers add olive oil or some other carrier oil and heat it to 212°F / 100°C for a couple of hours. This is when the CBD and other cannabinoids are infused into the oil.

Along with the problems with strength, it isn’t the most precise method either, and you’re likely to get plenty of impurities alongside the cannabinoids you’re interested in. The strength issue essentially comes from the fact that you can’t get the oil to evaporate away and leave you a purer extract.

Lipid extraction is essentially the same thing, except you use fats to absorb the cannabinoids instead of something like olive oil. The most common choice for this is organic coconut oil, but it still isn’t widely used by companies.

Processing the CBD Oil Extract

Once companies have produced the base extract, there are a couple more key steps to maximize purity and minimize contamination: winterization and distillation.

Winterization

Winterization forms a crucial part of the process of making CBD oil, because it separates out the lipids present in a raw extract.

Manufacturers combine the extract with 190 to 200 proof alcohol and then freeze it for 24 hours or at least overnight. By the end of the process, the mixture is cloudy and ready to be filtered, generally with progressively finer-grained filters. Alcohol has a lower boiling point than oil, so after the filtration manufacturers simply heat the resulting liquid until the alcohol evaporates away.

This works because the unwanted waxy components are separated from the oil by the alcohol and freezing process, so they can be easily filtered out, and after evaporation, you’re left with a much purer oil. The downside of this is that some terpenes are also lost in the process. The necessity of winterization depends on the extraction method used, with CO2 dragging a lot of fats into the mixture, butane (or other hydrocarbon) based methods picking up a moderate amount and cold ethanol extraction minimizing it.

Short Path Distillation

The process of short path distillation basically involves heating the extract gradually to separate out specific elements from the mixture.

Different cannabinoids have different boiling points, so if the mixture is heated very slowly and precisely, at a specific time only one component is being vaporized. Producers then collect the vaporized components individually in distillation tubes, which are fed to some cooling coils which condense the vapor back into a liquid form which can be collected.

So through the process, specific cannabinoids can be extracted and any remaining impurities can be removed as well. Once the process is completed, not only can you have specifically collected, say, CBD and some terpenes, you can repeat it all over again with the new finished product to increase the purity further. After multiple rounds, you can reach 99 percent purity or higher, which is crucial if you aim to be producing an isolate.

However, if you recombine your choice of cannabinoids and other chemicals, then you can still use this approach to produce broad-spectrum or even full-spectrum extracts.

Conclusion

So now you understand what it means when a company says they use CO2 extraction or if you saw something advertised as a “butane hash oil,” as well as the importance of processes like winterization and distillation.

It should go without saying that the processes described here have a lot of complicated details that we haven’t gone into, but for your purposes as a consumer just understanding the basics is more than enough to make an informed choice.

You can easily find out if your chosen brand or product is of good quality – check if they have a Certification of Analysis (COA).